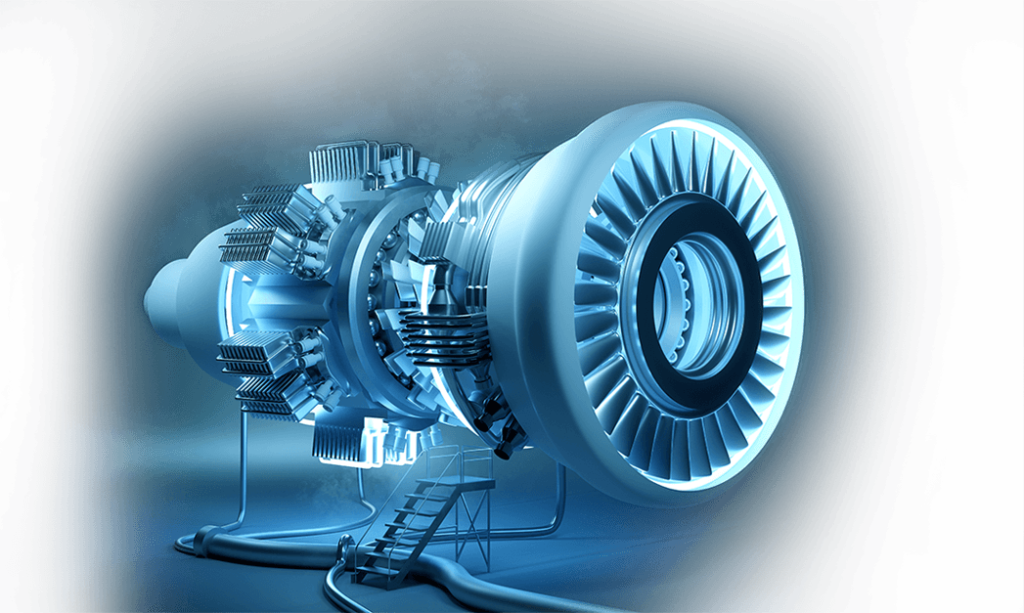

Integrated 3D CAD/CAM Solution Powered by Self-Developed 3D Geometric Modeling Kernel

Designed for the whole process of product development

Featuring the fastest kernel for Solid-Surface Hybrid Modeling, non-solid mold parting and smart CNC machining strategies from 2-axis to 5-axis

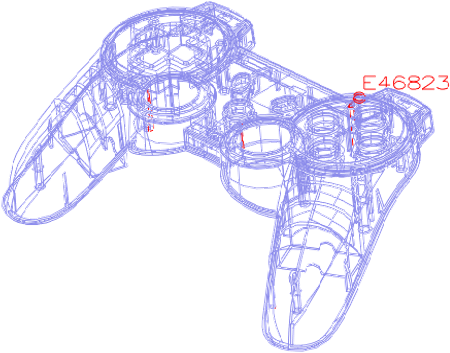

ZW3D supports translating non-native CAD data of different 3D modeling systems CAD data exchange with multiple suppliers becomes so easy

Innovative Solid-Surface Hybrid Modeling to Maximize Design Flexibility

Abundant tools can help handle your complex assemblies via both top-down and bottom-up design. You can flexibly assemble, manage, and edit the components, view different status, update associated models, etc.

Reliable verification tools can help ensure the manufacturability of your design

• 2D drawings, with detailed information of dimensions, tolerances and annotations, can be easily created for manufacturing and inspection. Plus, they can be updated automatically as models or assemblies change.

• PMI tools allow you to make dimensions and annotations intuitively on 3D entities, making design collaboration a piece of cake.

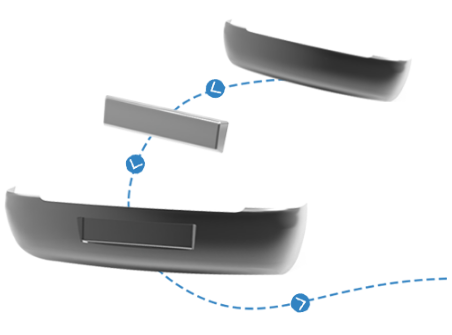

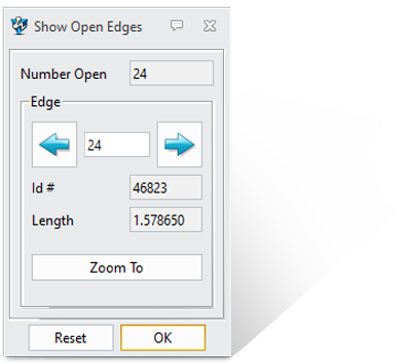

Various geometric topological states, such as repeated surfaces and open edges can be accurately analyzed and repaired.

With geometric gaps efficiently filled and missing surfaces rebuilt, a complete solid model is ready to ensure data quality.

Various geometric topological states, such as repeated surfaces and open edges can be accurately analyzed and repaired.

With geometric gaps efficiently filled and missing surfaces rebuilt, a complete solid model is ready to ensure data quality.

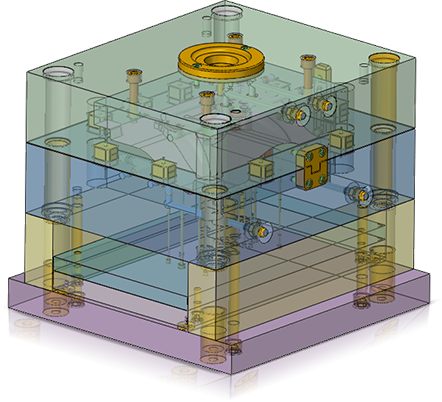

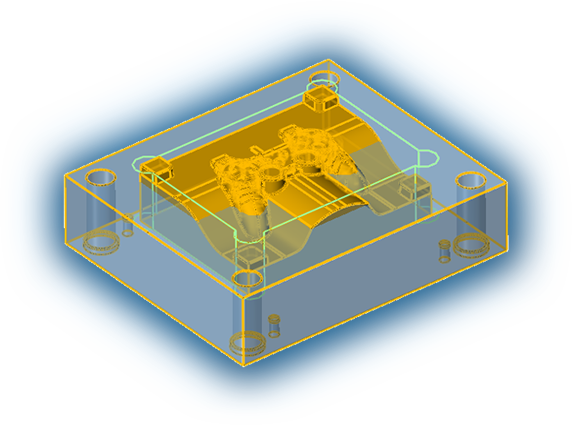

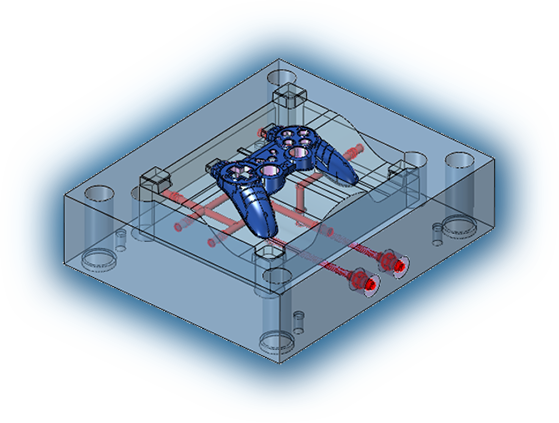

The built-in library of mold bases and standard parts can be modified and personalized, meeting requirements of different countries and companies.

Specialized tools are provided to quickly create runners, cooling systems, slides and gates, which can also be easily and intuitively modified.

• Easy-to-use electrode extract tools allow you to deal with complex electrodes quickly.

• Electrodes and 2D sheets can be correctly created in batches to save your time.

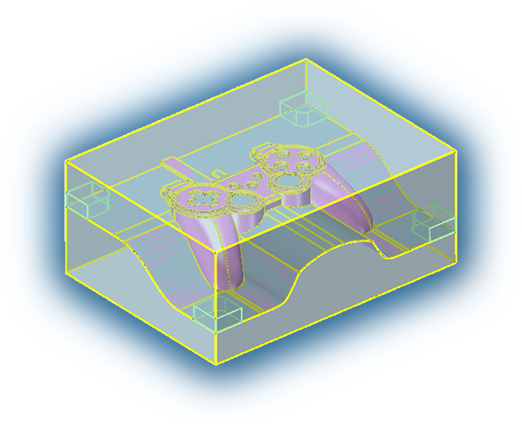

• More than 40 types of machining operations are available to facilitate efficient machining, so that you can deal with all kinds of manufacturing work at ease.

• No matter on Nurbs or STL geometry, desired toolpaths, or even undercut toolpaths can be easily generated.

• 5-axis milling provides a complete solution for indexing and 4 to 5-axis machining, and it’s also able to work with STL file.

• Comprehensive functions, like Swarf, Drive Curve, Drive Surface, Flow Cut, Side Cut and Point Control are available to extend machining capabilities for different scenarios.

Numerous verification and simulation tools are delivered to ensure feasible, reliable and safe machining.

• Solid Verify can be used to simulate the actual machining process and analyze the excess materials, realizing reliable and efficient machining.

• Analysis functions help detect collisions and gouges between tools and stocks, tables, clamps, etc.

• The accurate calculation of the minimum tool hang length ensures the safety of machining.

ZW3D Post offers advanced post-processing capabilities to convert cutter location data (APT-CL) into machine-specific codes (GM codes) required by CNC machines. All classes of 3 to 5-axis milling machines are supported.